In today’s fast-paced manufacturing and engineering landscape, speed and adaptability are crucial. Programmatic design and parametric CAD modeling enable engineers and designers to respond quickly to changing requirements without sacrificing quality. Rather than manually creating multiple variants of a product from scratch, programmatic approaches leverage parametric modelling, automation tools, and custom logic to generate countless configurations effortlessly.

At Transient Geometry, we specialise in harnessing the power of tools like Autodesk Inventor’s iParts and iLogic to deliver agile, scaleable solutions. With these methodologies, what once took hours or days can now be achieved in mere minutes, providing a significant competitive advantage in product development cycles.

Note: A 3D parametric CAD model of a minimalist table, showcasing how programmatic design enables adjustable dimensions and customisable features for efficient furniture production.

Understanding Programmatic CAD Design

What is Programmatic Design?

Programmatic design refers to the process of automating the creation, modification, and management of CAD models through rules, parameters, and scripted logic. This ensures that each variant remains consistent in quality and meets all design criteria. Furthermore, it is particularly useful for reducing time spent on repetitive tasks.

How Programmatic CAD Accelerates Workflow

The Benefits of Automated CAD Modeling

By shifting from a manual to an automated process, automation in design allows you to reap several benefits.

- Time Savings: Eliminates repetitive tasks and speeds up design iterations.

- Cost Reduction: Reduces labour costs associated with manual modelling.

- Consistency: Ensures every generated variant meets quality standards.

- Scalability: Easily handles more complex products with numerous variables.

A Practical Example: Automating Table Design with Parametric CAD

The Initial Challenge

Consider a simple table design that has four variables—four lengths, two different leg styles, one or two people wide, and if you want dividers or not—leading to 32 possible combinations. For instance, traditionally, modelling even three variants by hand might consume hours. As a result, imagine how much longer it would take to build all 32 variations individually.

The Programmatic Solution

Using iParts and iLogic, we created a programmatic CAD design model that can adapt to any combination of these four variables. The result? Generating all 32 variants took less time than it would have taken to model just three variants traditionally.

The time savings become even more pronounced as the complexity of the product increases. With more variables (and thus exponentially more possible configurations), the programmatic approach drastically reduces development time, freeing designers to focus on innovation rather than repetitive tasks.

Leveraging iParts and iLogic for Customisation

iParts: Tabulated Designs for Faster Variation

iParts enable you to create tabulated designs where a single model can represent multiple configurations. By defining parameters such as dimensions, materials, and features in a table, you can quickly switch between variants without building separate models from scratch. This concept is further detailed in our Tabulated Designs with iPart page, where you can learn how to set up and manage these structured variants.

iLogic: Embedding Rules and Logic

iLogic, a rule-based automation tool within Autodesk Inventor, allows you to define logic that responds to changes in parameters. For example, if the table’s length exceeds a certain dimension, iLogic rules can automatically adjust the support structure. This ensures that no matter how you alter the inputs, the resulting configuration always meets your design requirements.

By combining iParts with iLogic, you can easily manage large product families. This approach turns your CAD model into a smart template that can generate an almost infinite number of variants at the click of a button.

To learn more about iLogic, head over to Autodesk’s article on Logic functionality.

Scaling Your Approach with Automation

Beyond Part Modelling

Programmatic design isn’t limited to part geometry. At Transient Geometry, we’ve developed custom plug-ins that automate the creation of drawings for each variant. Furthermore, this feature is invaluable in maintaining documentation consistency, as every new combination is accompanied by detailed, accurate, and up-to-date technical drawings.

To learn more about how we automate drawings, explore our Automating Dimension Placement in Inventor Drawings page. Here, we showcase how parameters from the model drive dimension placement and annotations, ensuring every variant’s documentation is ready in seconds.

Integration with External Data

Programmatic design and parametric CAD modeling become even more powerful when integrated with external data sources. For example, by linking CAD models to spreadsheets or databases, you can manage parameters externally and update numerous configurations simultaneously. This approach aligns well with principles like Design for Manufacturing (DFM), enabling rapid iteration and streamlining the entire product development lifecycle.

For more information on linking design parameters with external data, check out our Automating Data Entry into Autodesk Inventor with Excel, which showcases how you can import data into Inventor to drive multiple variants.

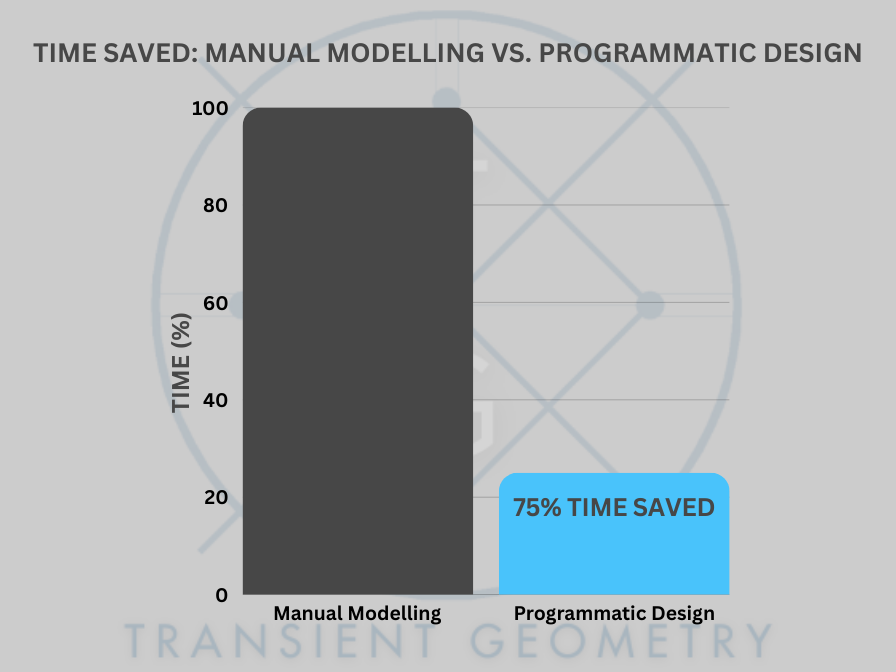

Visualising the Benefits

Before and After: A Comparison

Manual Approach

- Scenario: Designing 3 table variants

- Time Invested: Several hours or even days, including repetitive CAD modelling

- Documentation: Each drawing created manually, risking inconsistencies

Programmatic Approach

- Scenario: Creating 32 table variants

- Time Invested: Less than it took to model 3 variants manually

- Documentation: Every variant’s drawing generated automatically with a custom plug-in

The comparison is stark: programmatic design not only provides a shortcut for generating multiple variants but also, importantly, ensures that your documentation process is equally efficient and reliable.

Best Practices for Implementing Programmatic Design

When integrating programmatic design into your workflow, consider these best practices:

- Start with Clear Parameters: Identify which dimensions, materials, or features you need to vary.

- Use a Consistent Naming Convention: Keep parameters clearly named and organised.

- Test Rules Early: Validate your iLogic rules with a few test scenarios before scaling up.

- Leverage Existing Assets: Use standard parts, iParts, and iLogic code snippets to reduce duplication.

- Continuous Improvement: Regularly review and refine your rules and parameters for ongoing efficiency gains.

By following these guidelines, you can maximise the benefits of programmatic design and maintain a robust, future-ready development process.

Real-World Impact and Future Prospects

Meeting Market Demands

As markets evolve and customer preferences shift, being able to rapidly test and produce new variations helps you stay competitive. With programmatic design, responding to new trends or client requests is straightforward. Want a table with a different height or material? Adjusting a parameter is all it takes.

Embracing Customisation

Increasingly, customers expect personalised products. Programmatic design makes mass customisation feasible by enabling you to produce tailored solutions at scale without incurring prohibitive time or cost penalties.

Staying Ahead with Transient Geometry

At Transient Geometry, we stay at the cutting edge of CAD automation, regularly researching new techniques and integrating emerging technologies. Our goal is to ensure you have the tools and support you need to thrive in a rapidly changing industry.

Transform Your Design Process

Ready to transform your CAD workflow and tap into the power of programmatic design? Contact Transient Geometry today to discuss how our custom solutions, training, and consultancy services can help you achieve faster design cycles, greater consistency, and improved ROI.

Achieve faster design cycles, greater consistency, and improved ROI with Transient Geometry’s custom solutions, training, and consultancy services. Contact us to get started today!

Leave a Reply