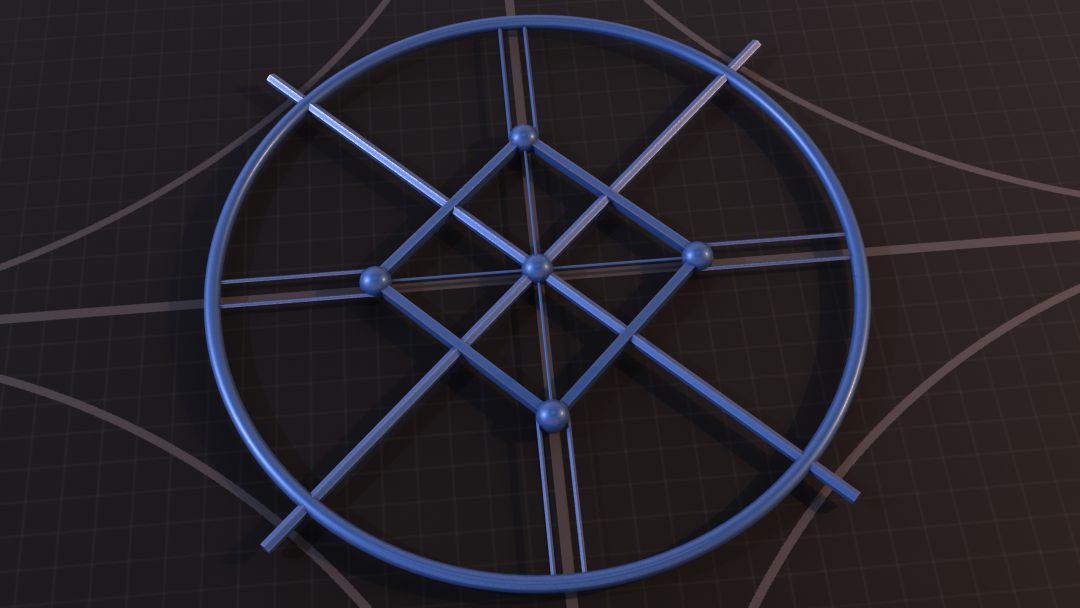

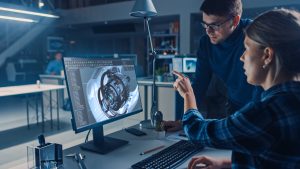

Autodesk Inventor Consultancy & Automation Solutions

Enhance your design process with advanced Autodesk Inventor consultancy services from Transient Geometry.

We specialise in delivering innovative CAD design solutions, tailored automation workflows, and bespoke engineering advancements to meet the specific needs of your projects.

Whether you’re looking for customised plug-ins, batch modifications, or full design automation, our expert consultants ensure your business stays ahead of the curve.

Advanced Design Automation

Revolutionise your workflow with custom engineering automation solutions that streamline complex design tasks. Our automation experts help you integrate cutting-edge tools that save time and boost efficiency, tailored precisely to your project’s requirements.

Custom CAD Plug-ins

Our team develops bespoke CAD plug-ins that extend the capabilities of Autodesk Inventor.

From custom user interfaces to data validation, we can create any tool you need, reducing manual work and saving valuable time.

Tailored Engineering Solutions

We offer custom CAD design solutions to meet the exact requirements of your engineering projects. Whether you need automated workflows or project-specific support, our experts are here to assist at every stage of your process.

Batch Modifications

Simplify repetitive tasks with batch modifications that automate common design changes. We help you establish efficient workflows that eliminate redundant steps, ensuring quicker project turnaround times.

Consultancy Services

Take advantage of our UK-based Autodesk consultancy services to guide your project from concept to completion. Whether you need help with software integration, process automation, or plug-in development, our consultants bring the experience and expertise to deliver bespoke solutions.

-

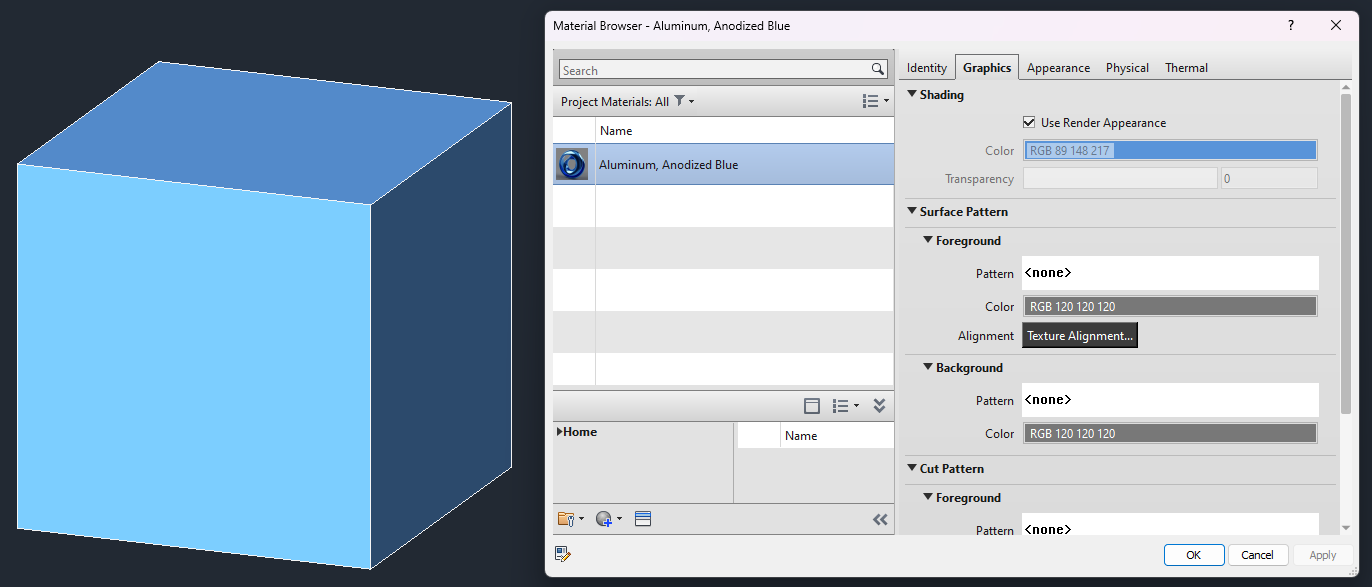

Importing Materials in Revit

Importing materials in Revit can be challenging due to limitations in API access. Revit, like Autodesk Inventor, relies on a standard material library, but unlike Inventor, it does not provide direct programmatic access to the material browser. How It Works: Importing Materials in Revit To import a material into a Revit project, follow these steps:…

-

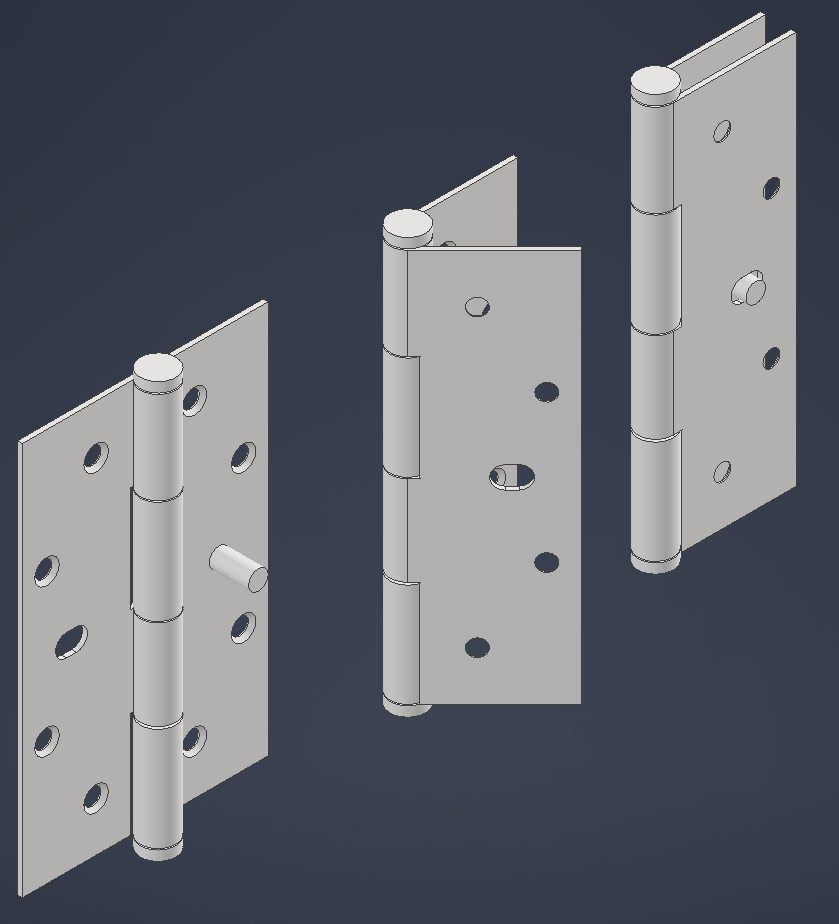

Using Different Model States in Autodesk Inventor

In design engineering, managing components or assemblies in multiple configurations is crucial for creating adaptable and efficient designs. Take, for example, a door hinge. It may need to be displayed in open and closed positions within different assemblies or in the same assembly at various times. Handling these variations effectively ensures streamlined workflows and consistency…

-

Selecting Start, Mid, and End Points on a Line in Inventor

When adding annotations to drawings in Autodesk Inventor, it’s often useful to select specific points along the edges of objects, such as the start, midpoint, or endpoint of a line, similar to how you would when adding dimensions. Inventor’s API provides access to this selection system through the PointInferenceEnabled property. By setting this property to…

-

Speed optimisations for searching iPart variants

Using iParts in Inventor makes it quick and easy to create hundreds of part variants. When working with Inventor’s API, it also simplifies locating the correct part since you only need to know the location of the factory file and search within for the variants, rather than finding the exact part file. However, searching for…

-

Automating Dimension Placement in Inventor Drawings

When working with multiple variants of a part, creating drawings for each variation can be tedious and repetitive. By cleverly using Inventor’s attribute system in conjunction with custom code, it is possible to fully automate the creation of drawings. In the following example, we will focus on placing dimensions, as these are often the most…