What can be automated?

Any task that can be deconstructed into a set of defined rules can be automated. There’s virtually no limit to the complexity or quantity of rules, as long as all inputs and outputs are quantifiable and not abstract. To automate tasks it simply becomes a matter of instructing the computer on how to adhere to these rules. The method you choose depends on what best suits your specific needs and circumstances; there is no one-size-fits-all solution. Flexibility and adaptability are key when determining the most effective automation approach for your unique requirements.

Autodesk Inventor offers many ways to automate your tasks

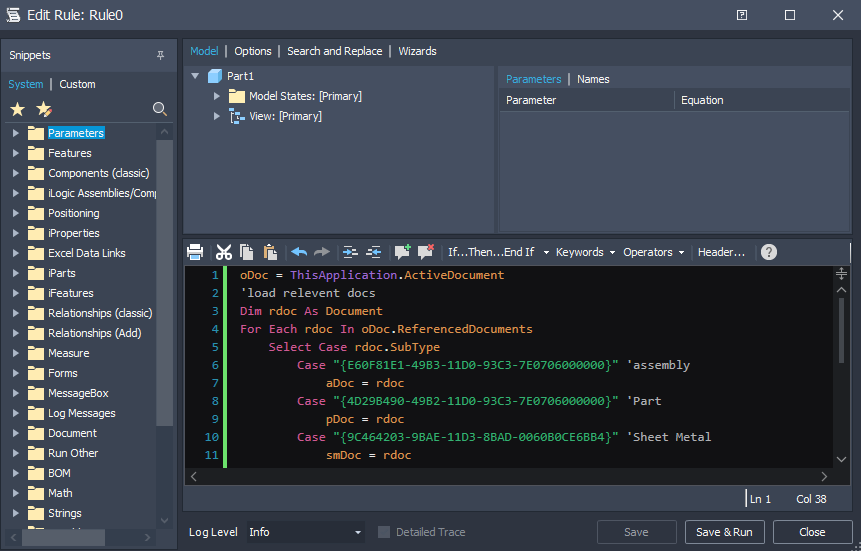

Inventor’s iLogic is a powerful tool that empowers engineers and designers to streamline their design processes, enhance efficiency, and minimize errors. By automating repetitive tasks and making it easy to adapt designs to changing requirements. iLogic boosts productivity and frees up valuable time for innovation. iLogic gives the user access to both a simplified instruction set along with Inventors full API making it easy for beginners to learn while also allowing for more complex programs to be created.

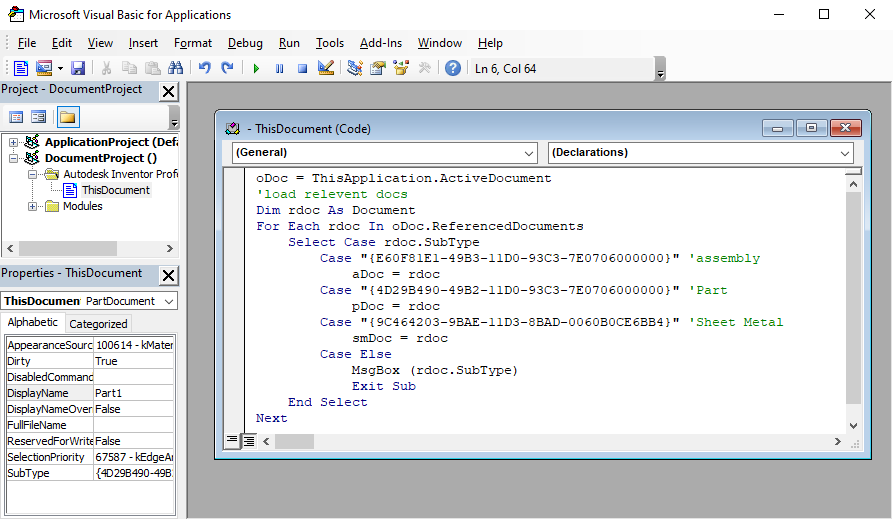

Inventor offers extensive support for macros through Microsoft Visual Basic for Applications (VBA), providing users with access to a familiar VBA editor, commonly found in various software. This VBA editor is equipped with built-in support for Inventor’s API, making it a robust choice for those seeking to automate tasks. While the VBA editor provides superior diagnostic tools compared to iLogic, it doesn’t offer access to simplified commands. Both iLogic and VBA enable users to save their programs directly to a part, facilitating custom scripting for individual components. Alternatively, you can save programs to Inventor itself, allowing the automation scripts to be applied universally across any part within your projects.

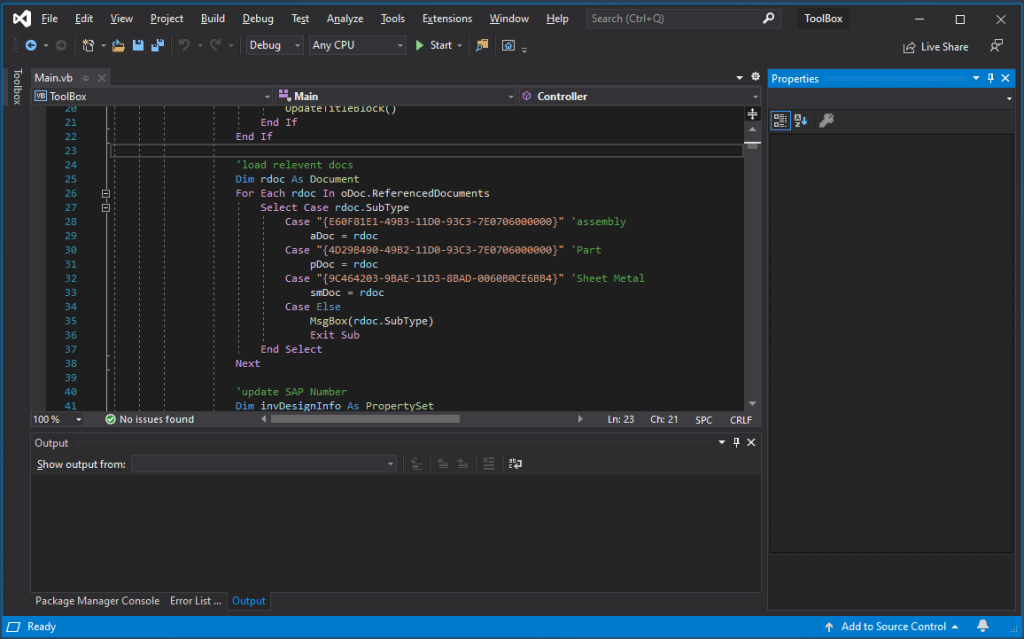

Inventor also provides the flexibility to extend its capabilities through third-party applications and plugins, enabling seamless integration with a wide array of other software solutions. If you find yourself needing to configure a set of parts based on an Excel table, it’s a breeze. Simply create a .NET application using either Visual Basic or C#. While this approach requires your own integrated development environment (IDE), it grants you access to advanced diagnostic tools available in these programming languages. Writing your own applications liberates you from being confined to a single instance of Inventor, allowing you to take charge of multiple instances for efficient parallel processing of parts and drawings.