-

Automating Skid Design with Parametric Modelling and iLogic

The Challenge of Designing Skid Variants Automating skid design can significantly reduce the time spent creating multiple variations, making the process more efficient. Skids may not be the most complex component to design, yet when each variation requires a new model and drawing, the time investment quickly adds up. Whether you’re accommodating different motor power…

-

Automating Batch Exports for Modern Manufacturing

Streamlining CNC Workflow with Automated File Exports In modern manufacturing, automating batch exports is essential for improving efficiency, reducing errors, and optimising workflows. Computer Numerical Control (CNC) machines rely on digital files like DXF (Drawing Exchange Format) and STEP (Standard for the Exchange of Product Data) for precision machining. While this digital process enhances accuracy…

-

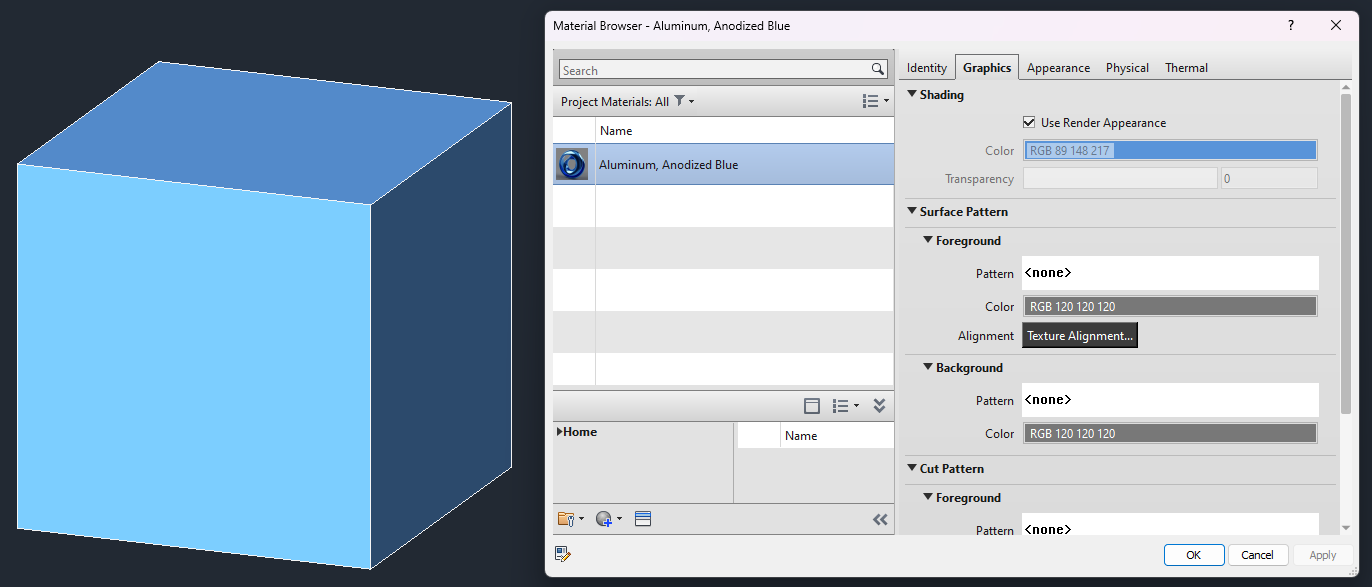

Importing Materials in Revit

Importing materials in Revit can be challenging due to limitations in API access. Revit, like Autodesk Inventor, relies on a standard material library, but unlike Inventor, it does not provide direct programmatic access to the material browser. How It Works: Importing Materials in Revit To import a material into a Revit project, follow these steps:…

-

Programmatic CAD: Faster Furniture Production

In today’s fast-paced manufacturing and engineering landscape, speed and adaptability are crucial. Programmatic design and parametric CAD modeling enable engineers and designers to respond quickly to changing requirements without sacrificing quality. Rather than manually creating multiple variants of a product from scratch, programmatic approaches leverage parametric modelling, automation tools, and custom logic to generate countless…

-

Optimised CAD for Automotive Piston Design Efficiency

In the competitive automotive industry, optimised CAD design for automotive pistons plays a crucial role in improving engine performance and fuel efficiency. Optimised CAD design for automotive pistons plays a crucial role in achieving these goals. Optimising piston design not only enhances engine efficiency but also boosts reliability and longevity. At Transient Geometry, we specialise…

-

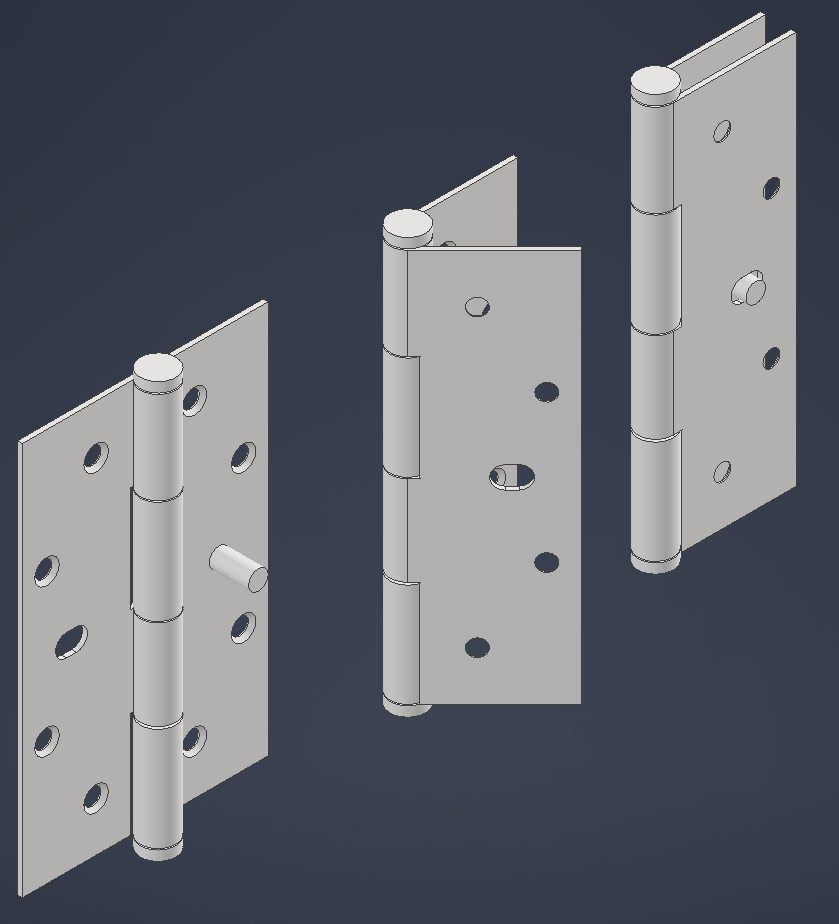

Using Different Model States in Autodesk Inventor

In design engineering, managing components or assemblies in multiple configurations is crucial for creating adaptable and efficient designs. Take, for example, a door hinge. It may need to be displayed in open and closed positions within different assemblies or in the same assembly at various times. Handling these variations effectively ensures streamlined workflows and consistency…

-

Selecting Start, Mid, and End Points on a Line in Inventor

When adding annotations to drawings in Autodesk Inventor, it’s often useful to select specific points along the edges of objects, such as the start, midpoint, or endpoint of a line, similar to how you would when adding dimensions. Inventor’s API provides access to this selection system through the PointInferenceEnabled property. By setting this property to…

-

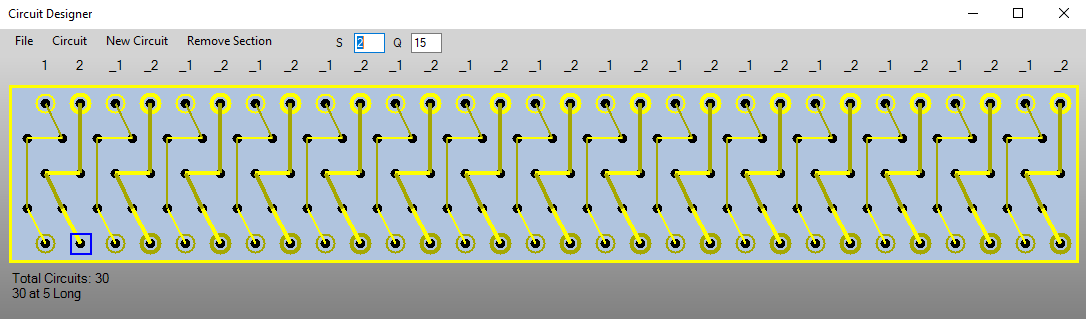

Creating a custom user interface

Revolutionizing Autodesk Inventor with a bespoke user interface, our solution accelerates the design process. Delve into our journey of crafting a custom interface tailored for speed, transforming heat exchanger circuit design. What is a custom user interface? A custom user interface is a tailored method enabling users to interact with a system in a manner…

-

Automating AutoCAD

Crafting a single use program for a large AutoCAD project. saving weeks of meticulous layout work through the use of a simple program to automate AutoCAD. Dive into how this bespoke solution streamlined equipment placement in complex, non-linear tunnels, revolutionizing efficiency within a singular project. A single use AutoCAD program The Project A client faced…

-

Speed optimisations for searching iPart variants

Using iParts in Inventor makes it quick and easy to create hundreds of part variants. When working with Inventor’s API, it also simplifies locating the correct part since you only need to know the location of the factory file and search within for the variants, rather than finding the exact part file. However, searching for…

-

Creating geometry from scratch using Inventors API

-

Automating Dimension Placement in Inventor Drawings

When working with multiple variants of a part, creating drawings for each variation can be tedious and repetitive. By cleverly using Inventor’s attribute system in conjunction with custom code, it is possible to fully automate the creation of drawings. In the following example, we will focus on placing dimensions, as these are often the most…

-

Fixing Attribute Helper for Inventor 2024

What is attribute helper Attribute helper is a tool that comes with Inventor that allows you to visualize, create, and edit attributes on a document. How to install attribute helper What broke Issues with COM Object Handling: After releasing a COM object, it is common practice to set the variable to nothing to prevent any…

-

Streamline Your Workflow: Automate Custom Memos with Power Automate

What is Power Automate? Power Automate is a powerful, yet simple-to-use, no-code automation tool provided by Microsoft. It enables users to create automated workflows between various applications and services to synchronize files, get notifications, collect data, and more. Power Automate helps streamline repetitive tasks and processes, freeing up time for more valuable activities. Scenario We…

-

Importing Star Data into Your Projects with Python

-

Placing objects in Autodesk Inventor using the API

Automating the placement of objects in Autodesk Inventor assemblies can significantly enhance efficiency in design workflows. This guide delves into using the Inventor API to position and orient parts within an assembly, focusing on the manipulation of matrices for precise control. Establishing a Connection to Inventor Begin by obtaining a reference to the active Inventor…